Porsche Mission R 1100 PS Electric Concept Study 2021

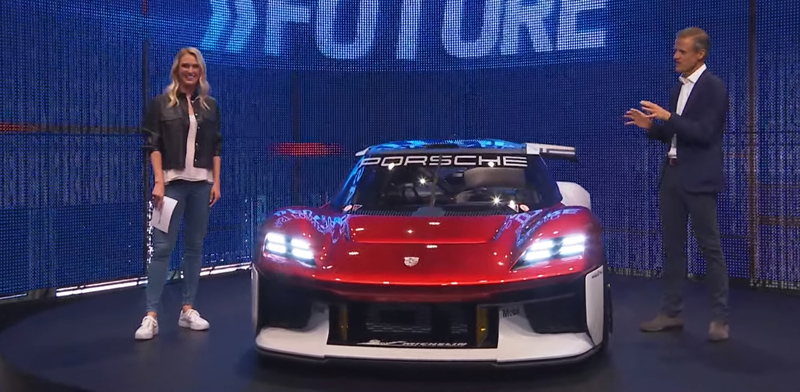

Stuttgart 2021 September 7th- The Porsche Mission R Concept was introduced at IAA MOBILITY 2021 in Munich, Germany. The Mission R concept car combines state-of-the-art technologies and sustainable materials, such as natural fibre-reinforced plastics, with a passion for racing. In addition to a progressive design, the extremely low-slung, all-electric competition car features the characteristic lines of the sports cars from Stuttgart-Zuffenhausen. The two newly developed electric motors incorporated in the Porsche Mission R deliver up to 800 kW (1,088 PS) in so-called qualifying mode. The battery capacity of around 80 kWh and the innovative recuperation system make sprint racing possible with no loss of output. "Porsche is the brand for people who fulfil their dreams. This is also true in motorsports. We experience our innovative strength on the race track, demonstrate courage in pursuing new avenues and delight car owners with sporting performance," says Oliver Blume, Chairman of the Executive Board of Porsche AG. "In addition to our involvement in the Formula E World Championship, we are now taking the next big step forward in electric mobility. The concept study is our vision of all-electric customer motorsports. The Mission R embodies everything that makes Porsche strong: performance, design and sustainability."

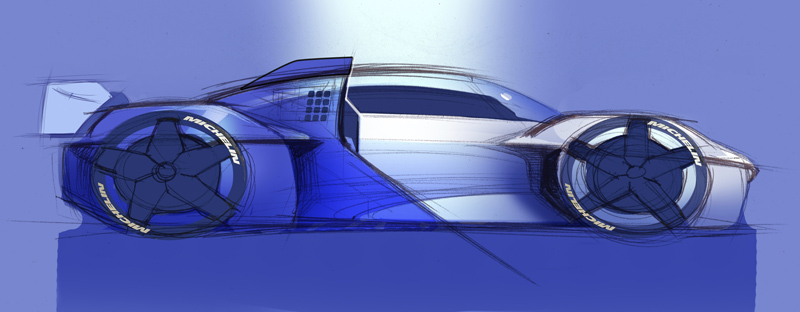

Customer motorsports enjoy a high level of esteem at Porsche. Since the start of the Porsche Carrera Cup Deutschland 31 years ago, the sports car manufacturer has produced and delivered more than 4,400 Cup cars from Weissach. A total of 30 one-make cup series are held worldwide on the basis of these reliable, high-performance racing cars. The latest version of the 911 GT3 Cup was not launched until the start of this year's 2021 motorsport season and is based on the 992 model generation. The Porsche Mission R provides an indication of what the future of one-make series with all-electric cars could look like. The all-wheel drive car delivering just under 1,100 PS in qualifying mode accelerates from zero to 100 km/h in less than 2.5 seconds. Top speed: over 300 km/h. On the race track, the electric racer achieves the same lap time performance as the current Porsche 911 GT3 Cup. Thanks to newly designed electric motors and battery cells – all equipped with innovative direct oil cooling – the Porsche Mission R concept study produces a constant power output of 500 kW (680 PS) in race mode. So-called derating, i.e. reduction of the battery‘s power output due to thermal conditions, has been eliminated. An electric motor with up to 320 kW (435 PS) powers the front axle, while a maximum of 480 kW (653 PS) is delivered to the rear. Thanks to advanced 900-volt technology and Porsche Turbo Charging, a good 15-minute break from racing is all that is needed to charge the battery from 5 to 80 per cent SoC (state of charge). Charging can take place with up to 340 kW. The Mission R also features a further development of Porsche Active Aerodynamics (PAA) with Drag Reduction System (DRS) on the nose section and rear wing. It comprises three louvres in each of the two side air intakes on the nose section as well as an adjustable, two-section rear wing.

In addition to the innovative, battery-electric drive concept, the body of the concept car also focuses on CO2 reduction and sustainability: it is largely made of natural fibre reinforced plastic (NFRP), the basic material of which is made from flax fibres obtained from farming. This ecological material is also used for the front spoiler lip, the diffuser and the side skirts. NFRP is used extensively in the interior of the Mission R, such as the interior door panels, the rear bulkhead and the seat.

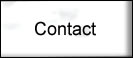

The interior design focuses on the driver in all areas. An ergonomically placed display between the controls on the steering wheel shows relevant data during the race. The monitor above the steering column shows the images from the side mirror cameras and the central rear-view mirror camera. A touch display to the right of the seat can be used to call up the driver's biometric data, for instance. Numerous other cameras in the interior can be used to provide exciting sequences for a live stream transmission. In the course of the last few years, with the Mission E (2015) and Mission E Cross Turismo (2018) concept studies, Porsche has given unmistakeable previews of its first all-electric sports car model series to come. The Porsche Taycan sports saloon (2019) and the Taycan Cross Turismo cross-utility vehicle (2021) closely resemble the two concept studies in terms of appearance and technology, and have already been successfully launched on the world markets – mission accomplished in other words. Now, with the Mission R, Porsche is presenting its vision of what customer motorsports will look like in the future. A look at the interior. Physical racing and esports merge in the Mission R. This is due to its driver cell monocoque, which is designed as a self-contained module and can be used in exactly the same form outside the vehicle as a simulator. This allows the driver to prepare virtually for their next race in a familiar environment. And the racing drivers of tomorrow can also use the driver cell to take part in esports events. The interactive possibilities offered by the Mission R are also aimed at a young and enthusiastic motorsports community. It is pre-equipped to provide a livestream broadcast from inside the car, and the driver can connect with their fans at the touch of a button. Fans can in turn communicate directly with the driver, for example by sending them likes in real time.

Particularly realistic race training on the simulator The seat, steering wheel, controls, adjustable pedals and screens form a compact unit in the Mission R and lie on the same axis as the driver. This allows the driver to concentrate on essentials during the race. At the same time, this driver module design enables a second driver's cell to be used outside the Mission R as a racing simulator. With the aid of movable, electrically controlled supports, the dynamic forces that impact on the driver can be simulated – when braking, for example, or as a result of rolling motions during fast cornering. Due to the familiar surroundings with identical display and control elements and the same full bucket seat, this kind of training can be extremely realistic and highly effective.

Ventilated full bucket seat, constructed by additive manufacturing The full bucket seat offers high protection potential for the driver. At the same time, it has an innovative design and is produced in part using additive manufacturing processes as what is known as a 3D-printed bodyform full bucket seat. The seat shell is made of the same natural fibre-reinforced material as the add-on parts in the exterior. The centre section of the seat, i.e. the cushion and backrest, is partly produced by a 3D printer. Porsche initially showed this alternative to the conventional upholstery used for bucket seats as a concept study in 2020 and conducted trials with selected customers during a test phase. As part of the new Performance Parts range, the 3D-printed bodyform full bucket seat is now available from Porsche Tequipment for all 911 and 718 models for which the current full bucket seat (order number Q1K) is offered. From February 2022, it will also be possible to order the seat ex-works, and it will then be integrated into the Porsche Car Configurator In the Mission R, the driver's seat is actively ventilated and upholstered in a breathable fabric that is made using a resource-saving 3D knitting process. The 3D-printed lattice structure also contributes to a good seat climate. These black, coarse-meshed elements are located, for example, in the area between the cushion and the backrest. Staggered arrangement of displays based on importanceMaximum driver focus is the credo of the Mission R. The key displays and controls are located along the same axis. This reduces distraction and helps the driver to improve performance by speeding up their reaction time. The information is hierarchically clustered into three levels:

Livestream broadcast from inside the car Two cameras mounted on the roof frame and on a rail above the passenger seat show what is happening inside the car during a race in real time. The live images can be transmitted directly to the community using a livestream button in the control panel. Fans can also communicate directly with the driver, for example by sending them likes. Integrated helmet ventilation and disinfectionIt goes without saying that motorsports equipment, such as a six-point safety harness, longitudinally adjustable pedals, safety nets and an extinguisher system, are also fitted. A new feature is the combination of helmet holder and dryer. In the Mission R, the driver’s helmet can be placed on a specially designed holder, which is positioned where the passenger headrest would be in a standard vehicle. During a break from racing, the helmet is first disinfected and then dried. Porsche has once again come up with something special for the interior ventilation system: fresh air now enters the cockpit directly via an adjustable inlet in the windscreen. This is a very effective and sustainable solution, therefore, compared with conventional designs with centrifugal fans and long air ducts routed from the front of the vehicle into the interior. For taxi rides, a second seat can be mounted on the passenger side. The control units, including cooler, which are combined into one electronic module, are located in the footwell. The driver's water bottle is also integrated into the seating arrangement. The expansion tanks for battery coolant, brake fluid and dampers are all neatly arranged beneath the rear window.

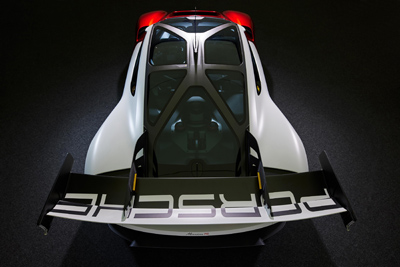

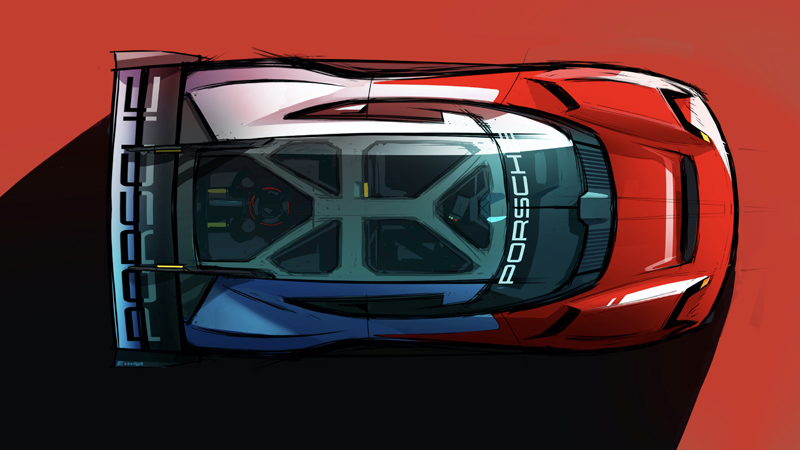

A look at the exterior. "Every Porsche has to be clearly recognisable as a Porsche. Many elements that we envisage in studies find their way later into production cars. This also applies to motorsports. Moreover, our customer sports vehicles are always based on production sports cars," explains Michael Mauer, Head of Style Porsche. "What this means in the case of the Mission R is that the car is packed to the gills with signs that hint of a future production model, and that, of course, means pure racing!“ At first glance, its extreme compactness is very apparent: it is 4,326 mm long and 1,990 mm wide. Characteristic of racing cars, the electric racer sits very low to the road (height: 1,190 mm). Its wheelbase is 2,560 mm.

The narrowly shaped cabin reduces the frontal area of the racing car and contributes to its outstanding e-performance due to lower air resistance. Cameras are mounted on the edge of the roof as a digital replacement for conventional wing mirrors. The colour concept is dominated by Porsche's standard Carrara White Metallic satin finish. By contrast, the front bonnet and front wings are painted in a high-gloss bright metallic red. This new shade extends into the doors, where it ends with a dynamic sweep. The spoilers are black to provide a sharper contrast. Dynamic proportionsDue to the transparent surfaces of the exoskeleton roof (see body and chassis section), the silhouette of the Mission R appears even lower than it actually is. The purist design approach is defined by the sleek cabin (the greenhouse), the roofline that slopes sharply downward to the rear (the flyline) and the pronounced shoulders of the wings. Much like the Porsche Cayman, the window graphics (daylight opening) end at the C-pillar with a counter-sweep. The A-pillars are black and visually blend the side window surfaces into a single unit, reminiscent of a helmet's visor. Another characteristic Porsche feature is the curved windscreen, which extends slightly around the corners. Form follows function – the driver benefits from better all-round visibility as a result.

Light emblem in the style of the electric PorscheIn characteristic Porsche style, the front bonnet slopes down between two sharply curved wings. The large triple-louvred side air intakes, the front splitter with its visible natural fibre mix and the flat LED headlights dominate the nose. The four-point light emblem is based on the design of the headlights on the Taycan electric sports car. Two vertically aligned towing lugs link up the front splitter and bumper visually. Since these are functional parts, they are also painted yellow.

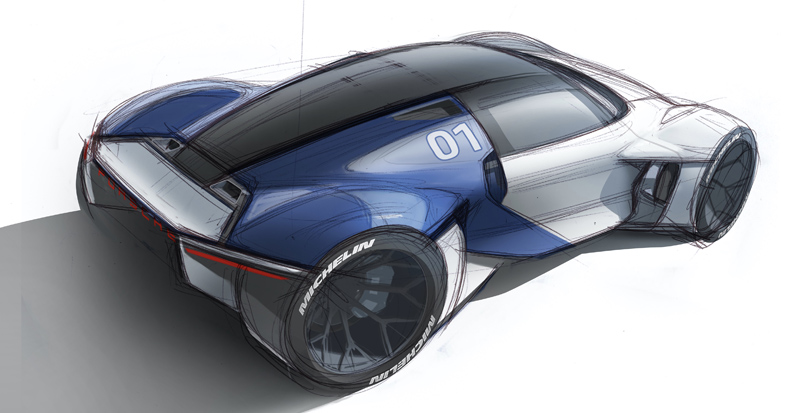

The rear of the car is dominated by the two aerodynamic components – the diffuser and the two-section spoiler, which is made of carbon. The designers have integrated the brake and rain lights into the profile of its wing plates. This makes them easily seen by following drivers, even in spray. At the rear, there is the signature Porsche light strip. It consists of a large number of illuminated vertical elements to the right and left of the lettering, which is also illuminated. The towing lugs at the rear are highlighted in colour, which is normal practice for racing cars. What makes them special is that they have been seamlessly integrated into the supporting structure of the vehicle. The charging connection for the battery is located in the middle of the rear window behind a flap. Mission R: With natural fibre components and carbon cageThe Mission R is the latest vision from Porsche. With this study of an all-electric GT racing car, the pioneer of sustainable mobility is revealing what customer motorsports could look like in the future. A look at the body and chassis. Many of the Mission R's add-on parts are made of natural fibre reinforced plastic (NFRP), the basis of which is a material made from agriculturally produced flax fibres. Producing this renewable fibre creates 85 per cent less CO2 than is the case with carbon fibre. The natural fibre material can be seen on the car’s exterior, such as the front splitter, the side skirts and the diffuser.

Sustainable natural fibre-reinforced plasticOn the exterior, the Mission R's doors, front and rear wings, sills/side panels and rear centre section are made of NFRP. The sustainable materials are based on agriculturally produced flax fibres – without interfering with the cultivation of food crops. The natural fibres are roughly as light as carbon fibres and deliver the stiffness required for semi-structural components with a low additional weight of less than 10 per cent. Compared with conventional plastics, natural fibres have an ecological benefit: 85 per cent less CO2 is generated in their production than in the comparable process used for carbon fibres. A collaboration between Porsche, the Federal Ministry of Food and Agriculture (BMEL), the Fraunhofer WKI and Swiss-based Bcomp began back in 2016, with the aim of making biofibre composite material suitable for automotive use. At the beginning of 2019, the Porsche 718 Cayman GT4 Clubsport was the first series-produced racing car to feature biofibre composite body panels. Innovative cage structure made of carbon fibre composite materialThe ‘exoskeleton’ is the name Porsche’s engineers and designers have given to the eye-catching carbon cage of the Mission R. The carbon fibre composite cage structure combines high protection potential for the driver with low weight and a distinctive look.

The protective structure forms the roof section and is visible from the outside. Like a half-timbered construction, it provides a framework around six transparent segments made of polycarbonate. This enables those racing the car to enjoy a new feeling of generous space. There are also some transparent surfaces, including a removable escape hatch for the driver, which is based on the FIA requirements for racing vehicles used in international competition. The roof solution with the exoskeleton is a modern interpretation of the Porsche Targa, in which the solid roll bar is also combined with a removable roof section. Aerodynamics designed for maximum downforceWith its advanced Porsche Active Aerodynamics (PAA), the Mission R can adapt its aerodynamic characteristics optimally to what the driver is doing on the race track. Its DRS (Drag Reduction System) comprises three louvres in the air intakes on each side of the nose section as well as an adjustable, two-section spoiler. For maximum downforce, the louvres are closed and the spoiler is deployed to its steepest position. To deflect as much air as possible in a race, the wheel arches are vented via openings at the top of each front panel. Furthermore, the front wheels are almost completely free in the rear area. Magnesium wheels with aeroblades and tyresThe Mission R rolls on 18-inch magnesium Cup centre lock wheels. With smooth-surfaced carbon aeroblades, the alloy wheels are also flow-optimised. Their five twin spokes are also milled, which saves weight.

Brake-by-wire braking and power steering With a double wishbone axle at the front and McPherson struts at the rear, the Mission R has independent suspension all round. Ball joints on all control arms ensure the chassis is connected to the suspension system with no play. Steel subframes also contribute to high-performance driving dynamics. In the brake-by-wire braking system, a control unit models the interaction between the hydraulic and electric brakes, which is known as brake blending. Due to the high recuperation output of up to 800 kW, the conventional brakes are subjected to a significantly lower load and could thereby be reduced in size. The diameter of the brake discs is now 380 and 355 mm at the front and rear, respectively. Six-piston callipers are fitted at the front, four-piston at the rear. The car is started with a battery status of 85 per cent (SoC). Recuperation is possible therefore in almost every driving situation. This means that, depending on the race track, more than 50 per cent of the energy can be recovered and is available for use. The steering is also electrified. With Electric Power Steering (EPS), a torque sensor receives the driver's intended directional change as a signal. On this basis, the control unit calculates the optimum steering assistance required. This information is passed on to an electric motor, which then provides the amount of power needed to complete the change in direction. The integrated air jack system facilitates quick tyre changes or repairs. The compressed air connections are located in the C-pillars.

source Porsche Media Archives Porsche Mission R 1100 PS Electric Concept Study 2021 : Wallpapers (click on image to enlarge)

|

|||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

.jpeg)

.jpg)