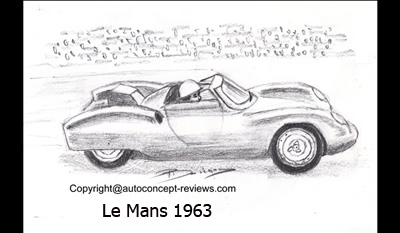

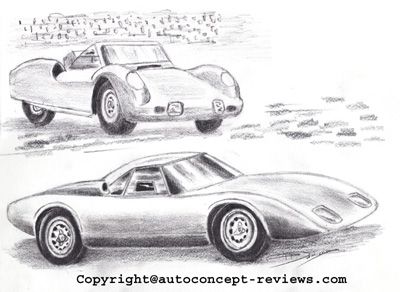

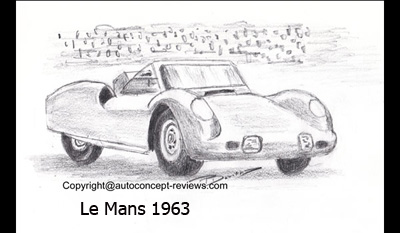

Rover BRM Le Mans Gas Turbine Prototypes 1963 1965The Automobile Club de l'Ouest (AC0) , organizers of the classic Le Mans 24 Hour race, had announced, in 1953, a special award for gas turbine cars participating in the event. The car was expected to cover at least 3500 km (2237 miles) in 24 hours which gives an average speed of 150 kph (93 mph). The gas turbine propelled racing car would run outside the qualification of the conventional contenders because there was no specific equivalence for this type of power unit. Rover and BRM entered successfully a Rover BRM in 1963 and again in 1965.

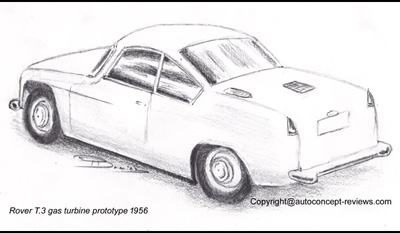

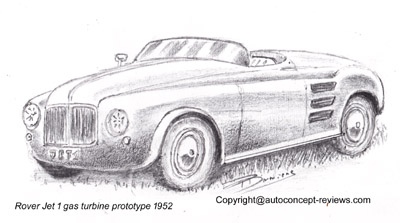

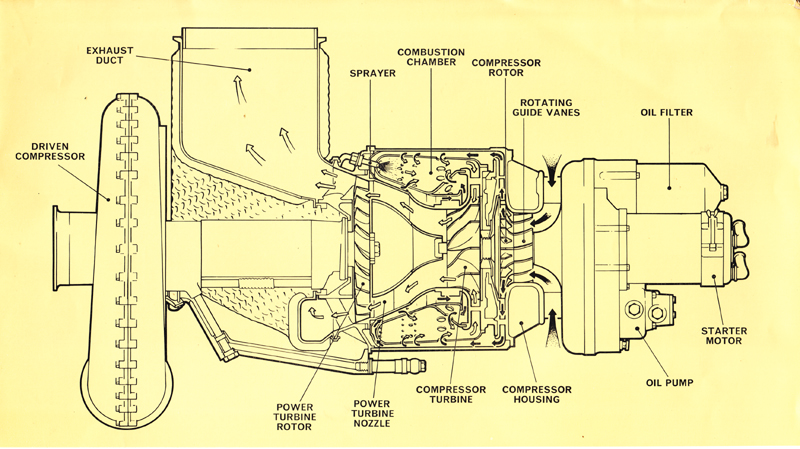

In 1945 Rover started developing small gas turbines; one intended application for a car manufacturer was obviously automobile propulsion. Several gas turbine propelled prototypes were completed; among them the four wheel drive Rover T3 two seats coupe in 1956 and the front wheel drive saloon Rover T4. The Rover T4 even completed a few demonstration runs in prologue of the 1962 Le Mans 24 Hours.

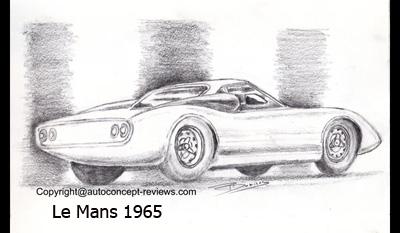

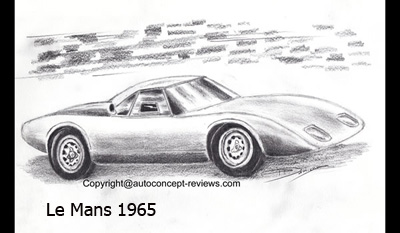

For the 1965 edition, Rover and BRM prepared an upgraded car with a coupe aluminium body. The Rover BRM was enlisted this time in the up to 2000cc Class. This time the gas turbine was equipped with a ceramic recuperator utilizing a new material prepared by Corning Glass. The car completed 284 laps or 3815 km (2371 miles) and finished in tenth position. It was driven by Jacky Stewart and Graham Hill. The average fuel consumption was 21 litre per 100 km (13.5 mpg). The Rover Gas Turbines Limited attempt at automobile propulsion was stopped there. The activity was transferred at British Leyland Motor Corporation Limited for the development of a gas turbine for heavy trucks with the Bus and Truck Division in a potential replacement for Diesel engines. The attempt was not successful and today it is essentially for aircraft that gas turbines substituted reciprocating piston internal combustion engines. One explanation is the difference between modern aircraft engines and the small gas turbines considered for automotive field. For various reasons the largest airliners use engines that are relatively complex, with compressors working at higher pressure ratio of 24:1 to 30:1 and inlet gas temperature as high as 1200°C for the turbine. Such engines compared to equivalent reciprocating piston engines offer operating economy and extended trouble free life between overhauls together with lower volume and weight. They represent also a very high capital cost that can be justified for an airplane but not for automobiles or trucks. Text and Illustrations Paul Damiens, Rover Gas Turbines Limited. Reference article: Gas Turbines for land transport, Nöel Penny, Science Journal April 1970. Wallpapers: Rover BRM Le Mans Gas Turbine Prototypes 1963 1965 (click on image to enlarge)

Related review

|

||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

||||||||||||||